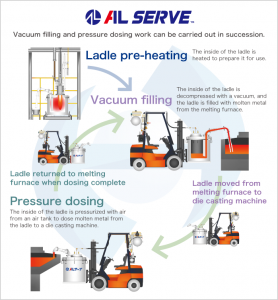

The AL Serve System, developed by HOEI METAL, revolutionizes the aluminum die-casting process by enhancing safety and efficiency in molten metal handling. Below is a breakdown of its process and benefits.

Process Overview

Vacuum Filling from Melting Furnace to Ladle

Pressurized Dosing to Die-Casting Machine Holding Furnace

Benefits of the AL Serve System

The AL Serve System enhances safety by eliminating the need for tilting ladles, reducing the risk of spills and accidents. Its automated controls minimize operator intervention, creating a safer work environment. Additionally, the system improves metal quality by minimizing exposure to air, reducing oxide formation, and ensuring higher purity of molten aluminum.

Operational efficiency is another key advantage of the AL Serve System. By combining filling and dosing in a single device, it streamlines operations and boosts productivity. Automated level detection and flow control further reduce manual labor and the potential for errors, making the entire process more efficient.

Why Choose the AL Serve System?

By integrating the AL Serve System into aluminum die-casting operations, manufacturers can achieve safer, more efficient, and higher-quality production processes. Many customers have already adopted this product and experienced its remarkable benefits.

Contact PT. Wilisindomas Indahmakmur today to learn more. As the only official representative of this product in Indonesia, we are ready to provide the best solutions for your aluminum die-casting needs.

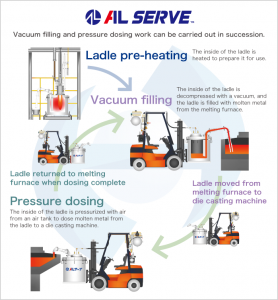

The AL Serve System, developed by HOEI METAL, revolutionizes the aluminum die-casting process by enhancing safety and efficiency in molten metal handling. Below is a breakdown of its process and benefits.

Process Overview

Vacuum Filling from Melting Furnace to Ladle

Pressurized Dosing to Die-Casting Machine Holding Furnace

Benefits of the AL Serve System

The AL Serve System enhances safety by eliminating the need for tilting ladles, reducing the risk of spills and accidents. Its automated controls minimize operator intervention, creating a safer work environment. Additionally, the system improves metal quality by minimizing exposure to air, reducing oxide formation, and ensuring higher purity of molten aluminum.

Operational efficiency is another key advantage of the AL Serve System. By combining filling and dosing in a single device, it streamlines operations and boosts productivity. Automated level detection and flow control further reduce manual labor and the potential for errors, making the entire process more efficient.

Why Choose the AL Serve System?

By integrating the AL Serve System into aluminum die-casting operations, manufacturers can achieve safer, more efficient, and higher-quality production processes. Many customers have already adopted this product and experienced its remarkable benefits.

Contact PT. Wilisindomas Indahmakmur today to learn more. As the only official representative of this product in Indonesia, we are ready to provide the best solutions for your aluminum die-casting needs.