Before we get into the main subject, we need to know what do we mean by “fluxes” in Aluminum Die Casting context.

Fluxes are special blends of typically solid, inorganic compounds designed for cleaning, degassing, grain refining, and/or chemistry modification of molten aluminum alloys and other purposes. A flux recipe varies depending on its purpose and other process variables, such as alloy and temperature.

To get into focus on what we will discover on this topic, we are ready to discuss with You on the function of fluxes as cleaning agents to aluminum alloys.

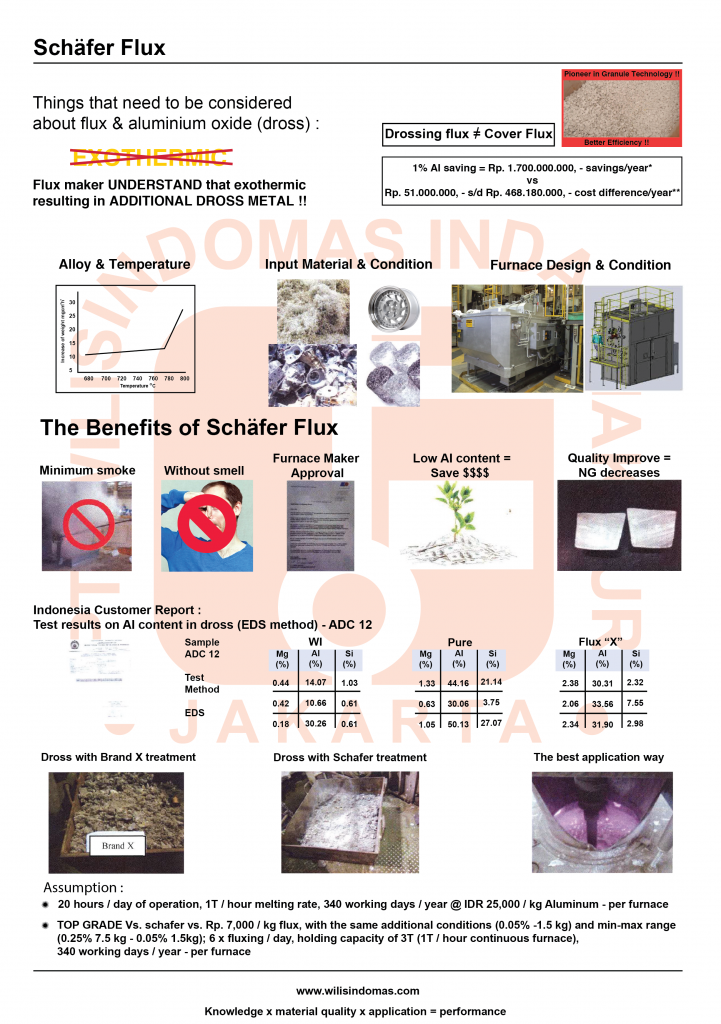

Please have a look at this one-page catalog, for things you need to know about fluxes as cleaning agents!

Read more

Figure 1. One-page Catalog of Schaefer Flux

So, what do we need to clean from molten aluminum alloys?

The answer is, we need to clean the aluminum alloy from Oxides and Hydrogen Gas that can potentially cause casting product defects.

Some other FAQs are:

- How to choose the right flux for each alloy?

- How does the flux work? Exothermic? Non-Exothermic?

- What is Sodium based flux? Sodium Free Flux? What are the effects to the process?

- How to reduce metal loss?

- How to count the efficiency?

- Do you have environmentally friendly flux? How to reduce the smoke caused by fluxing process?

To get the answers, to have more product knowledge and to see some trial reports comparison for both quantitative and qualitative analysis, please contact us, or leave your message by clicking the WhatsApp or e-mail inquiry buttons bellow! Our Product Specialist will contact you soon.