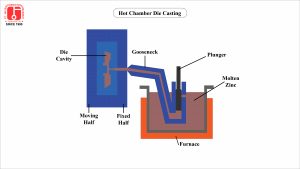

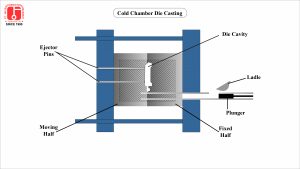

Die casting is a versatile and widely used manufacturing process in the metalworking industry. It involves injecting molten metal into a mold cavity under high pressure, creating parts with excellent dimensional accuracy and smooth surfaces. Whether you’re new to die casting or looking to deepen your understanding, here are some essential facts about die casting processes you should know.

1. High Precision and Accuracy

One of the most significant advantages of die casting is its ability to produce complex shapes with high precision and tight tolerances. This precision minimizes the need for secondary machining operations, saving time and reducing production costs.

2. Wide Range of Materials

Die casting isn’t limited to one type of metal. It can be used with a variety of metals, including aluminum, zinc, magnesium, and copper. Each material offers unique properties, making die casting suitable for a wide range of applications across different industries.

3. Efficient Mass Production

Die casting is ideal for large-scale production. Once the die (mold) is created, it can be used repeatedly to produce thousands of identical parts with consistent quality. This efficiency makes die casting a cost-effective solution for manufacturing high volumes of components.

4. Surface Finish and Aesthetics

Die-cast parts typically have smooth surfaces that require minimal finishing. This high-quality surface finish enhances the aesthetic appeal of the parts and reduces the need for additional post-production work, such as polishing or painting.

5. Strength and Durability

Parts produced through die casting are known for their strength and durability. The process allows for the creation of parts with a high strength-to-weight ratio, making them suitable for demanding applications in automotive, aerospace, and other industries.

6. Design Flexibility

Die casting offers immense design flexibility, allowing manufacturers to create intricate shapes and detailed features that would be challenging or impossible to achieve with other manufacturing methods. This flexibility enables the production of innovative and complex parts.

7. Cost-Effective Tooling

While the initial cost of creating die-casting molds can be high, the long-term benefits outweigh the investment. The molds are durable and can produce a large number of parts over their lifespan, making die casting a cost-effective option for long production runs.

Conclusion

Die casting is a highly efficient and versatile manufacturing process that offers numerous benefits, from high precision and durability to cost-effective mass production. Understanding these essential facts about die casting processes can help you appreciate its value in various industries and applications.

If you need high-quality die casting solutions, contact PT. Wilisindomas Indahmakmur today to learn more about how we can support your manufacturing needs.