Introduction to High-Pressure Die Casting (HPDC)

High-pressure die Casting (HPDC) is a versatile and efficient manufacturing process used in the production of complex metal parts. It involves injecting molten metal into a mold cavity under high pressure, which ensures precision, repeatability, and a smooth surface finish. HPDC is widely used in industries such as automotive, aerospace, and electronics, where strength, durability, and lightweight components are essential.

The Process of High-Pressure Die Casting

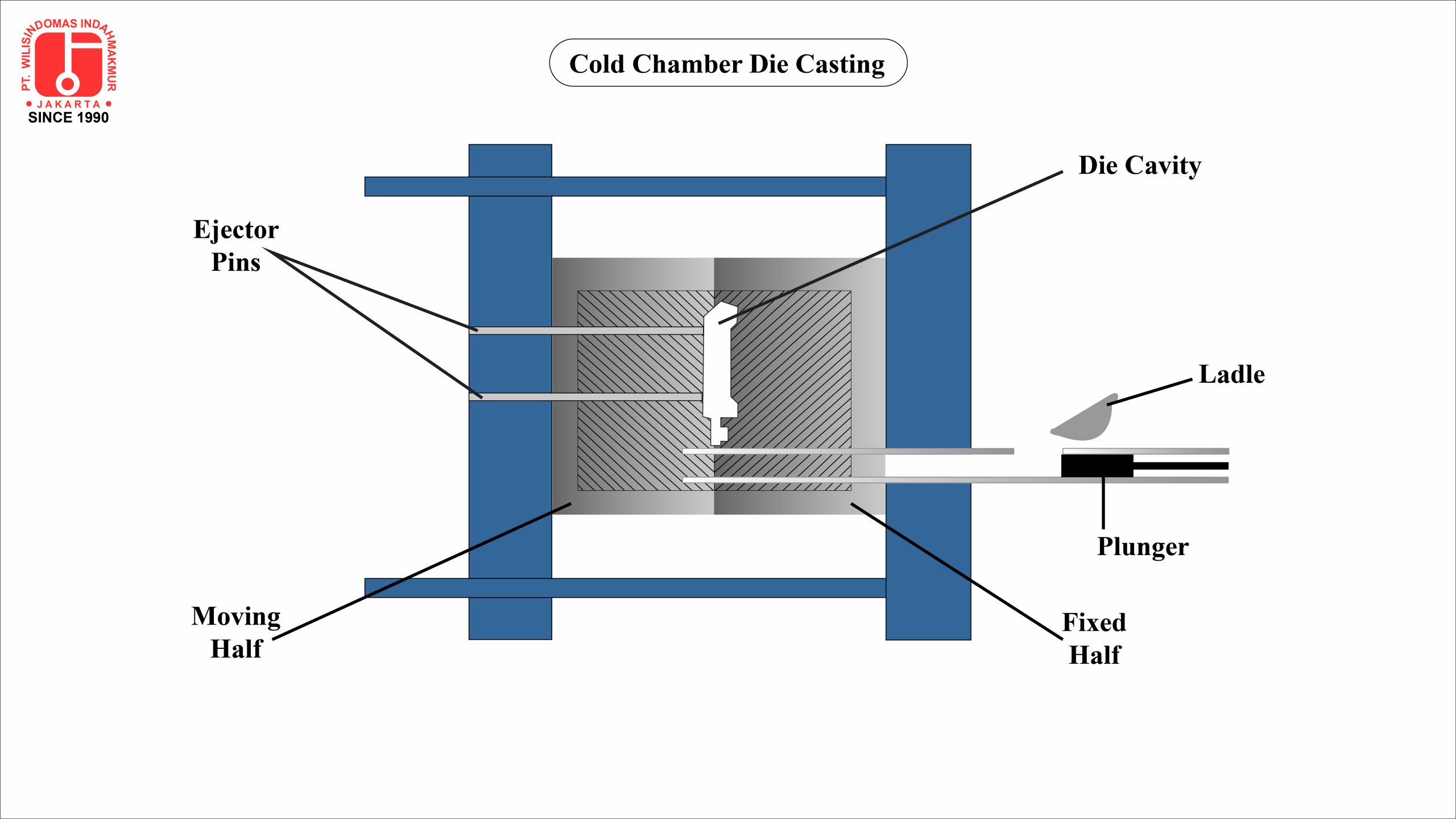

The HPDC process begins with the preparation of the mold, which is typically made from steel and designed to withstand high temperatures and pressures. Molten metal, usually aluminum, zinc, or magnesium, is then injected into the mold at high speed and pressure. This allows the metal to fill intricate designs and thin-walled sections with precision. After the metal solidifies, the mold is opened, and the cast part is ejected.

Advantages of High-Pressure Die Casting

- High Precision: HPDC produces parts with tight tolerances and excellent surface finishes, reducing the need for additional machining.

- Efficiency: The process is fast, allowing for high production rates, making it ideal for mass production.

- Material Efficiency: HPDC minimizes material waste, as the excess metal can be recycled and reused.

- Versatility: It can produce a wide range of parts, from small, intricate components to larger structural parts.

Applications of High-Pressure Die Casting

HPDC is used in various industries for producing components such as engine blocks, transmission cases, housing for electronics, and more. Its ability to create lightweight yet durable parts makes it essential in the automotive industry, where reducing vehicle weight is a priority for improving fuel efficiency.

Challenges in High-Pressure Die Casting

Despite its advantages, HPDC comes with challenges, such as the high cost of mold production and potential defects like porosity. However, advancements in technology, such as vacuum-assisted casting and improved mold designs, are helping to overcome these issues.

Conclusion

High-Pressure Die Casting is a critical process in modern manufacturing, offering a balance of precision, efficiency, and material savings. As industries continue to demand high-quality, lightweight components, the importance of HPDC will only grow.