Die casting is a manufacturing process in which aluminum molten is poured into steel molds. The molds –also known as tools or dies- are created using steel and are specially designed for each project. Aluminum, zinc, and magnesium are the most commonly used die casting alloys.

Functionality and Procedures

There isn’t one single process that can suit every project. The right process is always used for the right application. There are two different ways of manufacturing components: hot chamber and cold chamber die casting. In both manufacturing processes, the mold is sprayed with a release agent prior to the casting process in order to ensure that the subsequently cast part can be easily removed from the mold.

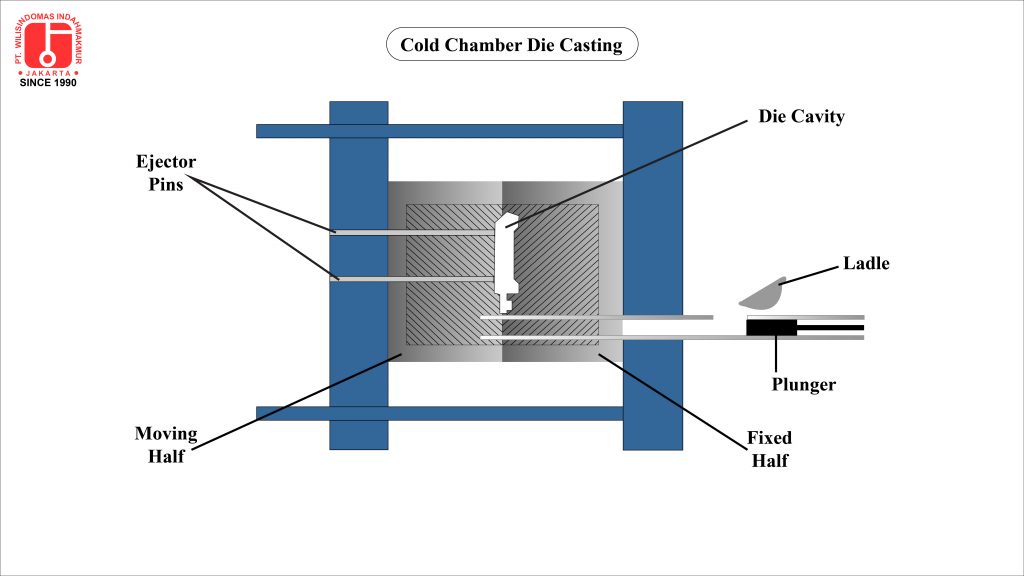

Cold Chamber Die Casting

Cold chamber die casting is used for all aluminum and copper-based die casting alloys. They are also used for certain zinc and magnesium die casting alloys. To produce a part, the alloy is filled into the casting chamber and pressed into the die casting mold through channels. After that, the aluminum melt solidifies and removed from the mold by an automatically operated ejector pin.

For more detail process of Cold Chamber Die Casting, you can click this.

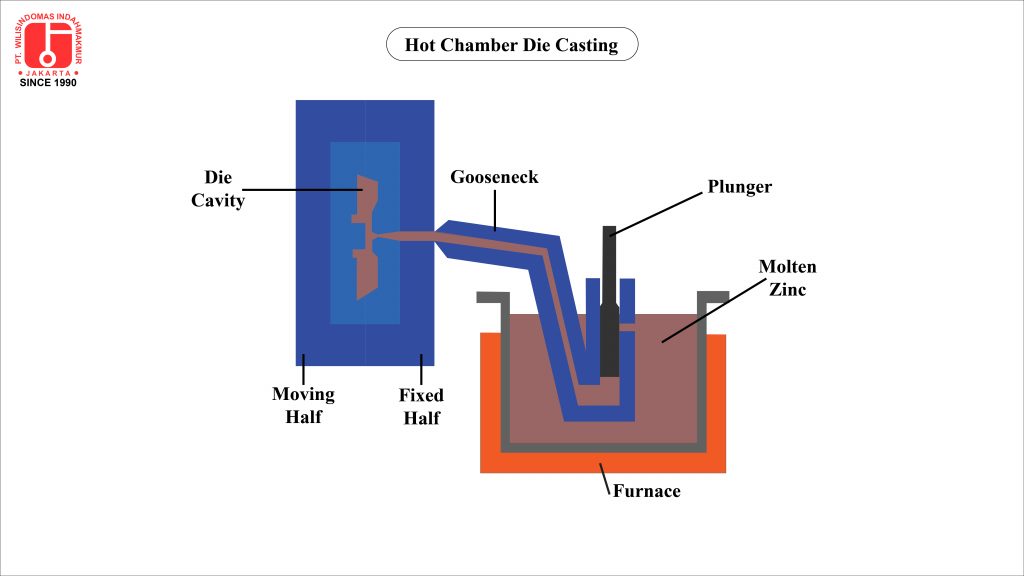

Hot Chamber Die Casting

Hot chamber die casting is usually used for metals with low liquid temperatures and metals that do not react to form alloys with metal die (steel) such as black lead, white lead, and zinc. The molten metal passes through a valve into the casting chamber, where it is pressed at high speed into the closed die casting mold through the gooseneck.

For more detail process of Hot Chamber Die Casting, you can click this.

Die Casting Advantages

Die casting can have significant advantages over other manufacturing processes, which often lead to major cost-saving, not only in the part price itself but also in the overall cost of production. You can combine multiple parts into a single part, eliminating assembly operations and lowering labor costs with the added benefits of simplified stock control and greater component consistency.

Other benefits include:

- Variable wall thicknesses

- Tighter tolerances

- Fewer steps from raw material to finished part

- Fast production cycle times

- Reduction in material scraps

- Long tool life especially for zinc and magnesium